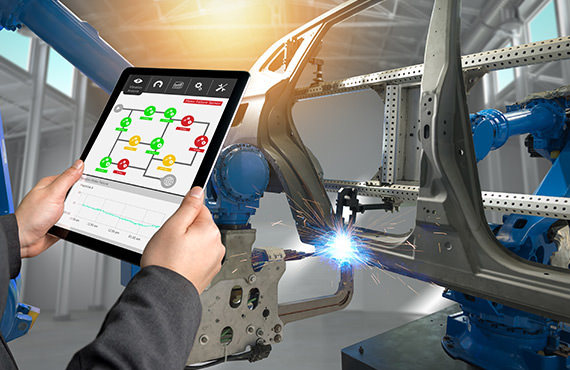

Vibration Analysis is the most predominant technique for Detecting, Monitoring & Analyzing the vibration levels and frequencies of industrial machinery, and using that information it determines the “health” of the machine, and its components. Early detection of vibration is essential in order to avoid critical damage, expensive repair and possibly health and safety hazards.

We have an experienced team of Vibration Experts and operate various Vibration Analysis programmes in a wide range of industries, including Iron & Steel, Cement, Sugar, Power Plant, Petrochemicals & Refineries, Pharmaceuticals, Oil & Gas Production, Engineering Industries, Mining, Oil Rigs, Electrical Rewinding, Atomic Energy, Defence, Marine, etc.

Our priority is the total health of your plant’s assets. Our Vibration Analysis Services can be availed on an “as needed” call out basis, or can be tailored into a Predictive Maintenance Program (PdM) that will improve reliability, increase safety, optimize asset life, and enhance production and operating efficiencies.