The QC LAB Family of Companies performs QC LAB bearing failure analyses for a variety of industries and companies in Bangladesh.

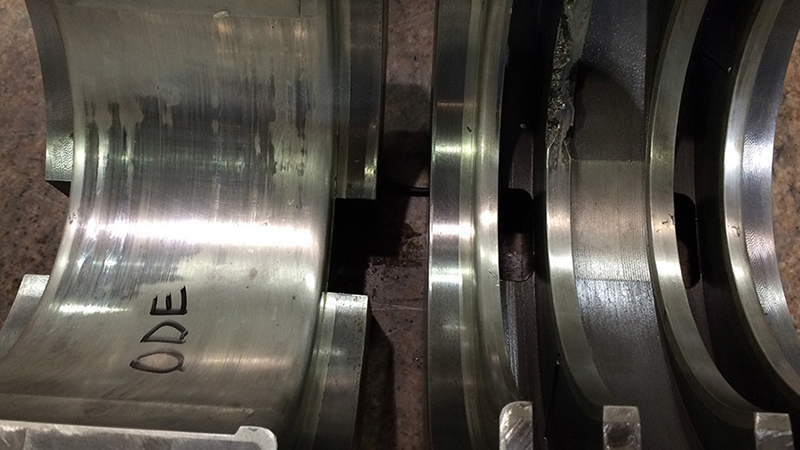

Typical causes of bearing failures are due to a variety of factors in many industrial machines, including contamination, misalignment, fatigue, improper lubrication, overloading, overheating, and corrosion. Our thorough testing evaluates degradation, design, manufacturing, and environmental conditions to find the root cause Vibration Analysis & Shock Pulse Analysis.

Our Failure Analysis Methods:

QC LAB examine damaged bearings, form opinions on the cause of failure, and determine measures to prevent reoccurrence. Our testing services include visual examination, scanning electron microscopy (SEM), metallography, hardness testing, and chemical analysis in Bangladesh. Along with our distinguished testing services, QC LAB applies a disciplined quality assurance program for assured results and reporting in Bangladesh.

Our process includes meeting the benchmark for conducting bearing failure analysis through the utilization of ASTM E2332, Standard Practice for Investigation and Analysis of Physical Component Failures, and other applicable specialized procedures in Bangladesh.

QC LAB systematic approach to testing and inspections combined with our ISO 9001:2015 registered quality program places us above the leaders in the failure analysis industry.

To learn more on how condition based monitoring can benefit your facility and for information on receiving a complimentary vibration analysis review, contact a QC LAB representative today at our +8801303643303. We currently perform vibration analysis testing in Sugar mills, Cement Plant, Steel Industry, Pulp & Paper Mills, power plant in Bangladesh.