Ground monitoring Survey involves the systematic collection and analysis of data related to the behavior and physical properties of the ground to assess its stability and response to environmental or structural changes. This process is crucial for understanding soil movement, groundwater levels, and other geotechnical factors that influence construction projects, infrastructure, and environmental safety. Ground monitoring Survey utilizes a variety of sensors and instruments, such as water level sensors, piezometers, inclinometers, extensometers, and strain gauges, to measure parameters like pressure, displacement, and strain beneath the Earth’s surface. These measurements are vital for detecting shifts in soil conditions, potential settlement, or ground deformation, and are key for applications in civil engineering, mining, and environmental management. By employing these tools, ground monitoring helps ensure the integrity of structures and the protection of surrounding environments through early detection and accurate assessment of ground movements.

Market Size and Growth

Market Size: The global Ground Monitoring Survey market is significant, with a valuation in the billions of dollars. This market encompasses services related to construction, civil engineering, mining, environmental protection, and infrastructure monitoring. It includes technologies and solutions for monitoring ground movements, water levels, soil conditions, and structural health, which are critical in ensuring the safety and stability of large-scale projects such as tunnels, dams, bridges, and skyscrapers.

Growth Rate: The market has been experiencing steady growth, fueled by increasing investments in infrastructure development, urbanization, and resource extraction. The demand for ground monitoring survey services is also driven by the need for early detection of ground-related risks and environmental protection. Technological advancements, such as the integration of remote sensing, IoT-enabled monitoring devices, and real-time data analytics, are further accelerating market expansion. As industries face rising environmental concerns and stringent regulatory standards, the ground monitoring survey market is expected to continue its upward trajectory, with growth particularly evident in the construction, transportation, and energy sectors.

Key Technologies of Ground Monitoring

- Water Level Monitoring: Tracks groundwater levels using sensors like float-based and pressure transducers, essential for flood management and construction site stability.

- Piezometers: Measure pore water pressure in soil or rock, helping assess soil stability and groundwater flow, particularly in geotechnical projects.

- Vibrating Wire (VW) Piezometers: Offer highly accurate pore pressure measurements through a vibrating wire sensor, ideal for long-term monitoring in challenging environments.

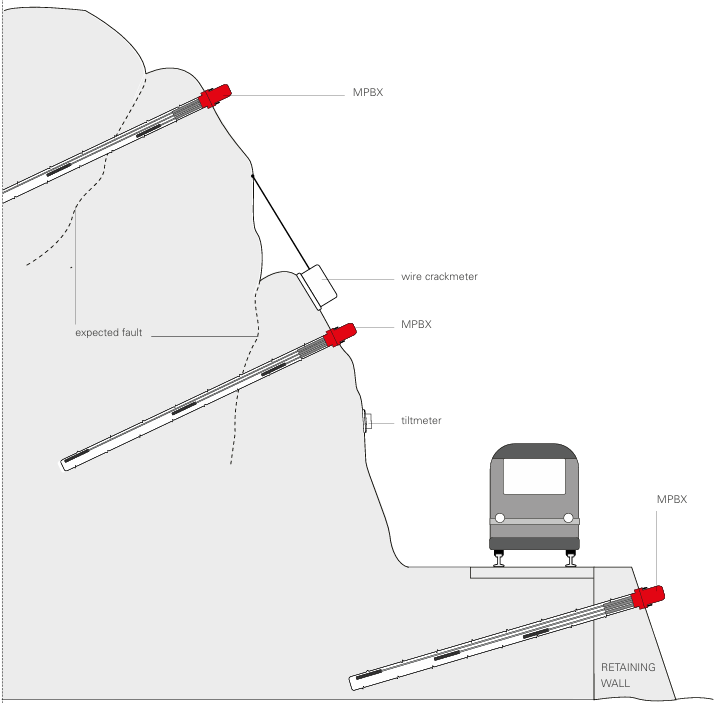

- Inclinometers: Measure angular displacement or tilt of the ground or structures, detecting ground movement or deformation, crucial for landslides or settlement monitoring.

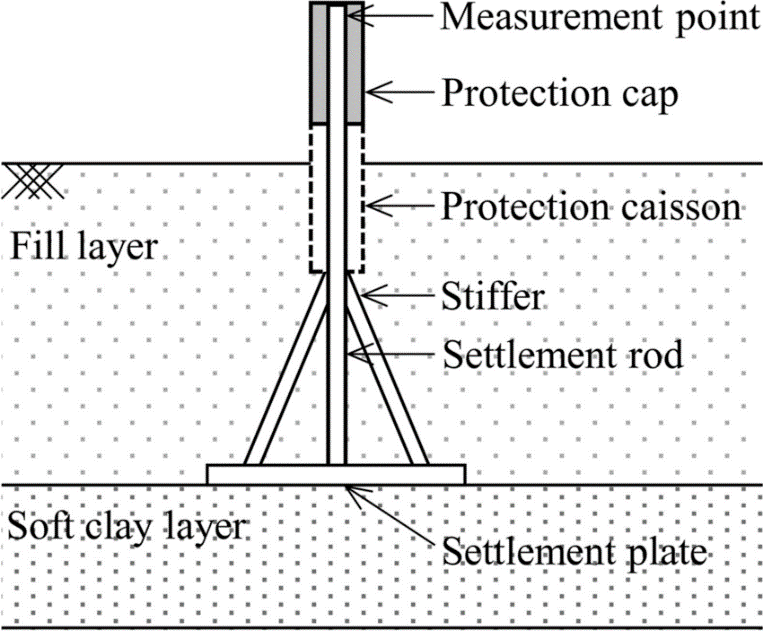

- Settlement Plates: Installed on the surface to measure vertical displacement of the ground or structures, used to monitor settlement during construction or soil compression.

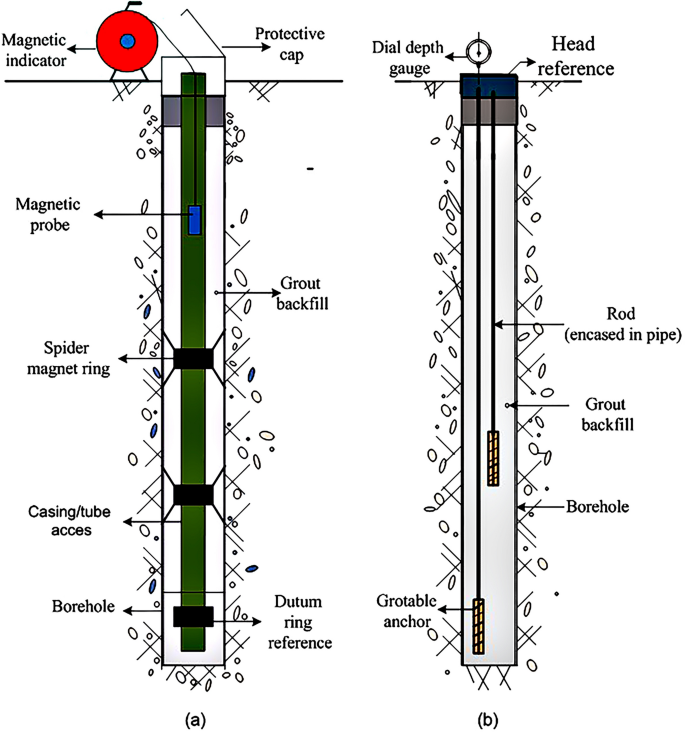

- Extensometers: Measure elongation or shortening in soil, rock, or structures, helping track deformation in tunnels, excavations, or foundations.

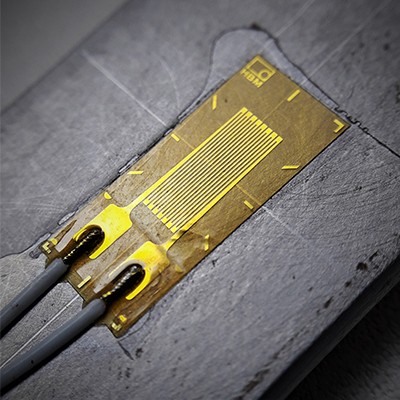

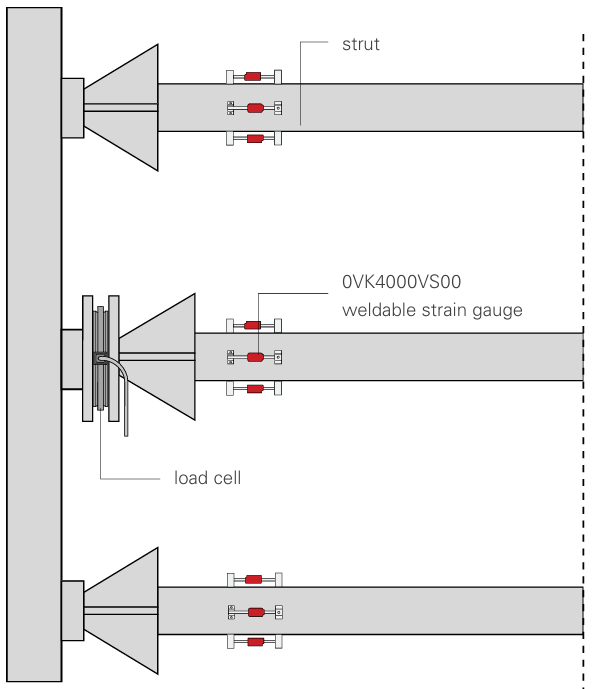

- Strain Gauges: Detect changes in shape due to forces like compression or tension, providing data for structural health monitoring in bridges, dams, and tunnels.

Regional Insights

The Ground monitoring Survey market varies across regions, driven by infrastructure development, environmental concerns, and the adoption of advanced technologies. Key regions include:

- North America: North America holds a significant share of the Ground monitoring Survey market, driven by ongoing infrastructure projects, urbanization, and strict environmental regulations. The U.S. and Canada are major players, using advanced monitoring technologies in construction, mining, and transportation sectors.

- Europe: Europe’s Ground monitoring Survey market growth is fueled by high investment in infrastructure, sustainable construction practices, and geotechnical monitoring for urban development. Countries like the UK, Germany, and France are leading in adopting innovative Ground monitoring Survey solutions for both civil engineering and environmental monitoring.

- Asia-Pacific: The Asia-Pacific region is experiencing rapid growth in the Ground monitoring Survey sector, driven by booming urbanization, infrastructure projects, and industrialization in countries like China, India, Bangladesh and Japan. These nations are increasingly deploying Ground monitoring Survey technologies for large-scale civil engineering projects and resource extraction.

- Middle East & Africa: In the Middle East, demand for Ground monitoring Survey is rising due to extensive construction activities, particularly in the Gulf region. Oil and gas exploration also drive growth in Ground monitoring Survey services. Africa is seeing increased investment in infrastructure development and mining, contributing to a growing demand for Ground monitoring Survey technologies.

- Latin America: The Ground monitoring Survey market in Latin America is expanding with significant infrastructure and resource extraction projects. Countries like Brazil and Mexico are adopting Ground monitoring Survey technologies to improve construction safety, monitor environmental impacts, and ensure infrastructure stability.

QC LAB SERVICE, Role:

As QC LAB Service. conducting Ground Monitoring Survey in Bangladesh, have a unique opportunity to play a significant role in both advancing international technology and contributing to the development of a Digital Bangladesh. Here how we make bridge international techniques and support digital advancement in the country-

Bridging International Techniques:

- Adopting and Localizing Advanced Technologies:

- Implement Cutting-Edge Monitoring Equipment: We utilize state-of-the-art Ground monitoring Survey instruments from global leaders, including piezometers, inclinometers, settlement plates, extensometers, and strain gauges. These technologies provide precise measurements for geotechnical stability, ensuring that we can monitor ground movements, pressure changes, and structural health with unparalleled accuracy.

- Customization for Local Conditions: We adapt these advanced technologies to local geological and environmental factors, ensuring their relevance and effectiveness. Whether monitoring soil conditions in challenging terrains or managing groundwater pressures in flood-prone regions, we tailor our solutions to meet specific regional needs.

- Training and Knowledge Transfer:

- Workshops and Training Programs: We host comprehensive workshops and training programs for local engineers, geotechnicians, and other stakeholders, offering exposure to international best practices and cutting-edge Ground monitoring Survey Our goal is to elevate the skillset of local professionals, ensuring that they are equipped to handle modern ground monitoring challenges.

- Knowledge Sharing: By collaborating with global experts, we facilitate knowledge exchange through technical seminars and project collaborations. This initiative helps local teams stay up-to-date with global advancements, ensuring continuous improvement in the use of Ground monitoring Survey

- Collaborative Projects: We partner with international firms and institutions to bring global expertise into local projects, ensuring adherence to international standards and quality certifications.

Contributing to Digital Bangladesh:

Leveraging Data for Digital Platforms:

- Geospatial Data Integration: We integrate ground monitoring data into digital platforms and GIS (Geographic Information Systems), improving accessibility and decision-making for stakeholders.

- Digital Databases: We develop and maintain digital databases of ground monitoring results, ensuring that key users such LGED, RHD, BBA, DMTCL, DNCC, DSCC, WASA, City Corporation, RAJUK, DPHE, CAAB, PWD, Bangladesh Railway Department, DESCO, NESCO, EGCB, PGCB and BPDB Etc. can access critical information for informed policy-making and planning.

Developing Digital Solutions:

- Software and Apps: We contribute to the development of software and mobile applications that visualize and analyze ground monitoring data, making data-driven decisions more accessible and actionable.

- Automation and AI: We explore AI and machine learning to automate data analysis, enhancing efficiency and predicting geological phenomena like soil movement, groundwater changes, and structural shifts.

Supporting Infrastructure Development:

- Smart Mapping: We use digital tools for infrastructure planning, helping to inform the development of roads, bridges, and urban projects by providing essential subsurface data. In Bangladesh main user of this are LGED, RHD, BBA, DMTCL, DNCC, DSCC, WASA, City Corporation, RAJUK, DPHE, CAAB, PWD, Bangladesh Railway Department, DESCO, NESCO, EGCB, PGCB and BPDB Etc.

- Disaster Management: We develop digital solutions that utilize ground monitoring data to predict and mitigate the impacts of natural disasters, contributing to better preparedness and response efforts.

By adopting international best practices and leveraging advanced digital tools, QC LAB Service. plays a vital role in enhancing the accuracy and efficiency of ground monitoring, supporting Bangladesh’s digital transformation and technological advancement.

Types of Ground Monitoring Survey:

- Water Level Monitoring (Water Level Sensors)

- Piezometric Monitoring (Piezometers)

- Vibrating Wire Piezometer Monitoring (VW Piezometers)

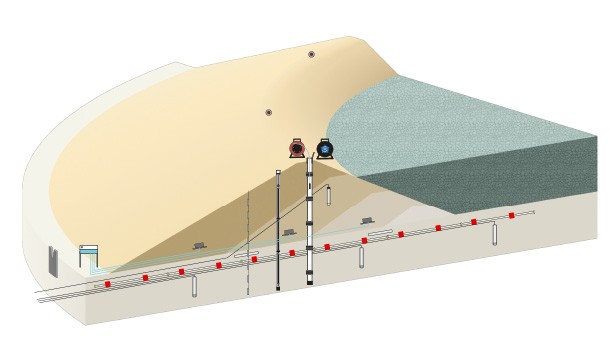

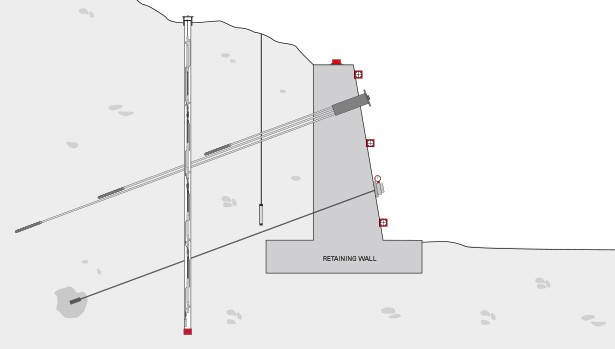

- Inclinometer Monitoring (Inclinometers)

- Settlement Monitoring (Settlement Plates)

- Extensometer Monitoring (Extensometers)

- Strain Monitoring (Strain Gauges)

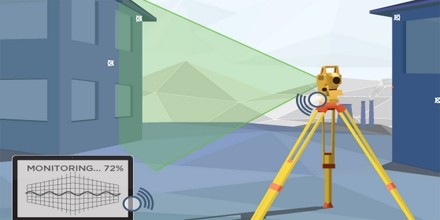

- Deformation Monitoring (Total Stations/GPS Monitoring)

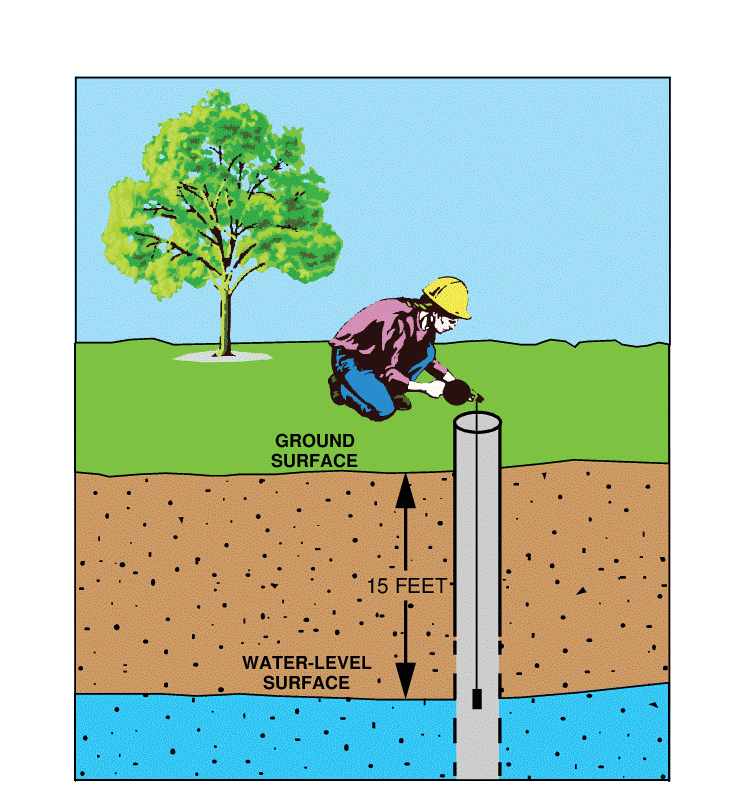

- Water Level Monitoring (Water Level Sensors)

Introduction:

Water level monitoring involves measuring the height of the water table or the level of water in wells, boreholes, or reservoirs. It is essential for managing groundwater resources and assessing flood risks in construction or environmental projects.

Test Procedure:

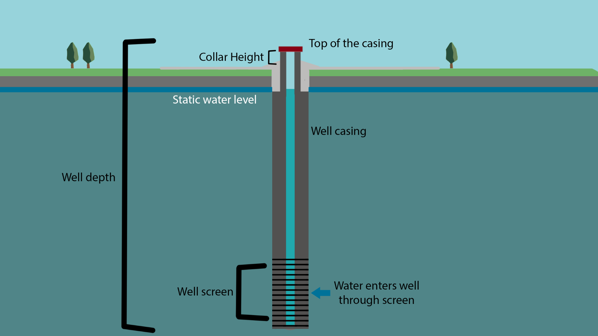

- Installation: Water level sensors are typically placed in wells or boreholes at various depths, depending on the monitoring requirements. A casing is used to prevent debris from entering the well, ensuring accurate readings.

- Measurement: The sensor works by detecting the position of the water level. Float-based sensors use a buoyant float attached to a cable that moves with water level changes, while pressure transducers measure the water column pressure.

- Data Acquisition: Data is transmitted in real-time to a data logger or control unit. The system records and stores the water level at regular intervals, which can be accessed remotely for analysis.

- Calibration: Regular calibration of the sensors is performed to ensure accurate measurements. This involves comparing sensor readings to known reference points or manually measured water levels.

Advantage:

- Continuous real-time monitoring of groundwater levels.

- Early detection of potential flooding or drought risks.

- Helps in assessing water availability for projects.

Applicable Area:

- Hydrology: Monitoring groundwater levels in aquifers.

- Environmental Management: Assessing flood risks and water quality.

- Civil Engineering: Managing construction site dewatering and drainage systems.

- Agriculture: Managing irrigation and water conservation efforts.

Future Scope:

- Integration with IoT and remote sensing technologies for smarter water management.

- Predictive analytics for flood forecasting.

- Automation of groundwater management systems.

Standard:

- ASTM D5126 – Standard Guide for Selection of Water Quality Monitoring Methods.

- ISO 10523:2012 – Water Quality.

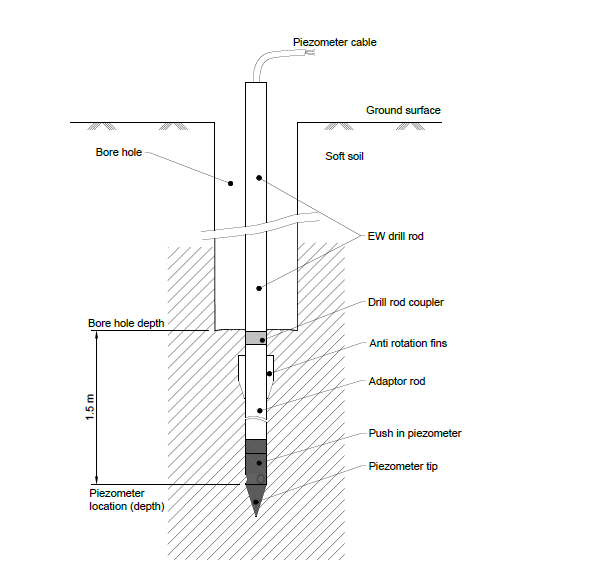

2. Piezometric Monitoring (Piezometers)

Introduction:

Piezometers are used to measure the pore water pressure in the ground. This is vital for understanding soil stability, especially in geotechnical investigations and the design of foundations, dams, and tunnels.

Test Procedure:

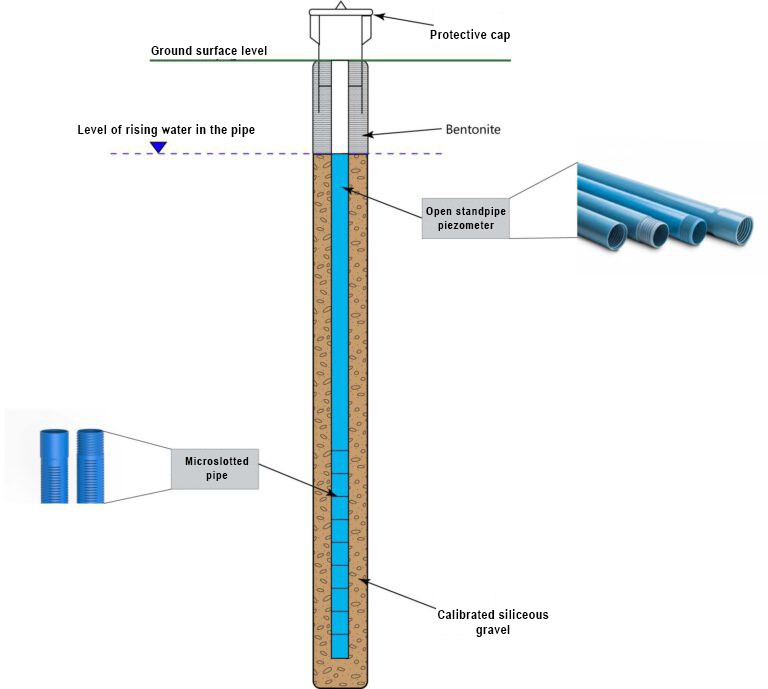

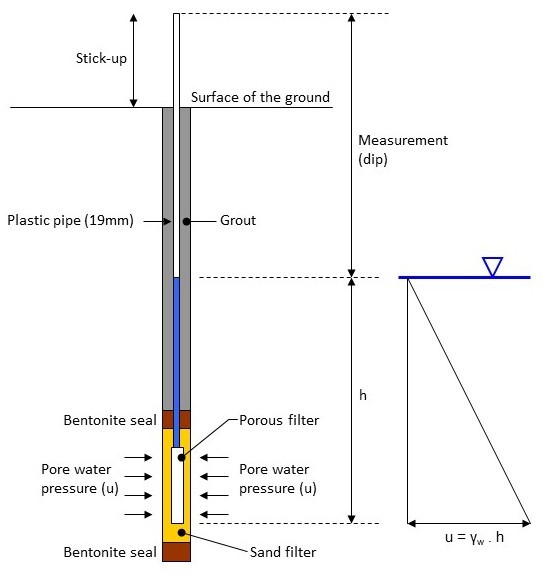

- Installation: Piezometers are installed in boreholes or wells at specified depths within the soil or rock strata. The installation involves placing the piezometer at a location where the pressure conditions need to be monitored.

- Measurement: Piezometers measure the pore water pressure within the surrounding soil by using either a mechanical or electrical sensor. In simple piezometers, a water column is used to indicate pressure, while electronic piezometers use pressure transducers.

- Data Acquisition: Pressure data is continuously recorded and transmitted to the surface using cables or wireless systems. Data loggers are typically used to store pressure readings at regular intervals for later analysis.

- Calibration: Piezometers are calibrated before installation and periodically throughout the monitoring period to ensure accurate pressure measurements, especially in changing environmental conditions.

Advantage:

- Provides crucial data for assessing soil stability.

- Helps in evaluating the risk of liquefaction and land subsidence.

- Useful for monitoring changes in groundwater pressure during construction.

Applicable Area:

- Geotechnical Engineering: Monitoring pore pressure in soils for foundation design.

- Civil Engineering: Assessing soil stability for infrastructure projects.

- Hydrology: Monitoring groundwater pressure in aquifers and dams.

Future Scope:

- Integration with real-time monitoring systems for automated alerting.

- Use of wireless piezometers for easier installation and data access.

- Enhancement in predictive modelling for soil behavior during seismic or load changes.

Standard:

- ASTM D5126 – Standard Guide for Selection of Water Quality Monitoring Methods.

- ISO 22282-3:2012 – Geotechnical investigation and testing — Piezometer testing.

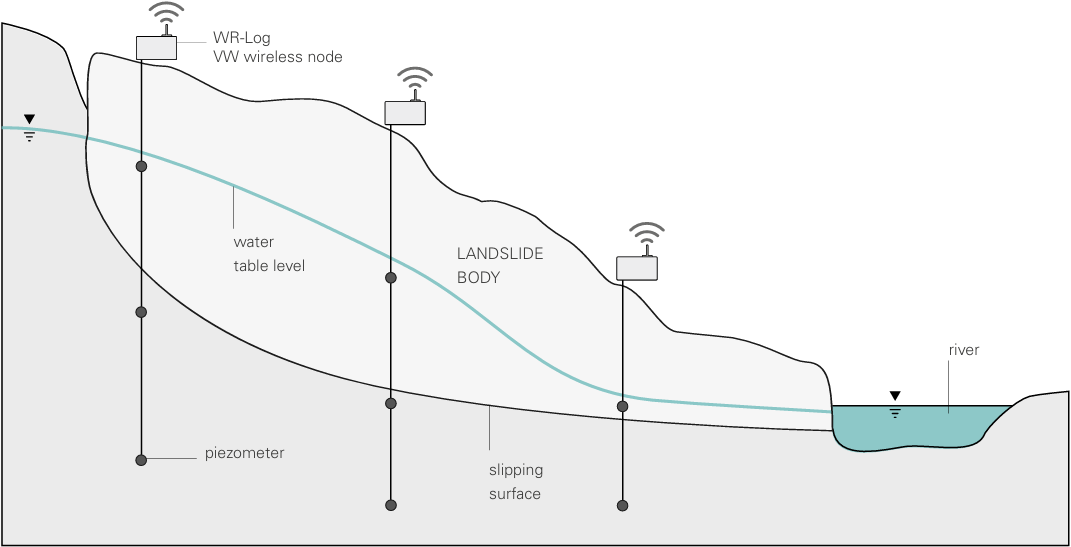

3. Vibrating Wire Piezometer Monitoring (VW Piezometers)

Introduction:

Vibrating Wire Piezometers (VW Piezometers) provide precise measurements of pore water pressure using a vibrating wire sensor. They are highly accurate and used for long-term monitoring, especially in challenging environments like deep boreholes.

Test Procedure:

- Installation: VW piezometers are installed in boreholes, with a casing protecting the instrument from the surrounding soil or rock. The sensor is positioned at a specific depth where pore pressure is to be measured.

- Measurement: The sensor consists of a vibrating wire that changes its frequency based on the pore pressure exerted by the surrounding water. The change in frequency is measured and converted into a pressure value.

- Data Acquisition: The frequency of the vibrating wire is recorded at regular intervals, and the data is transmitted to a central system. This data can be used to track long-term changes in pore water pressure.

- Calibration: Calibration is performed during installation by measuring the output frequency at known pressure points to ensure the accuracy of the measurements over time.

Advantage:

- High accuracy and reliability for long-term monitoring.

- Suitable for extreme depths or difficult environments.

- Minimal maintenance required.

Applicable Area:

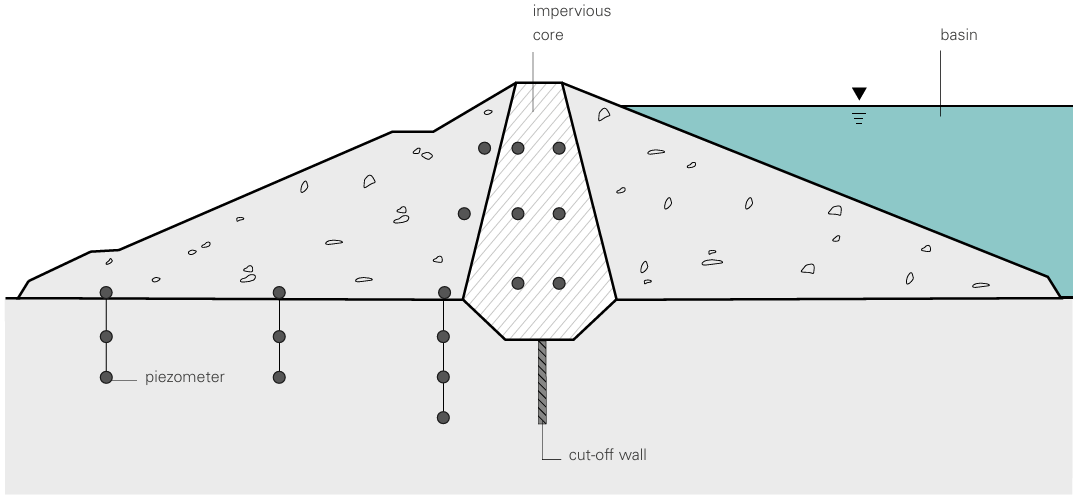

- Dam Monitoring: Ensuring the stability of dams and embankments.

- Slope Stability Monitoring: Detecting groundwater pressures in landslide-prone areas.

- Tunnel Construction: Monitoring pressure changes around underground tunnels.

Future Scope:

- Use of wireless sensors for remote monitoring in remote areas.

- Integration with AI to predict pressure variations based on environmental factors.

- Enhanced real-time data collection for more effective groundwater management.

Standard:

- ASTM D6680 – Standard Guide for Groundwater Pressure Measurement.

- BS 5930:2015 – Code of Practice for Site Investigations.

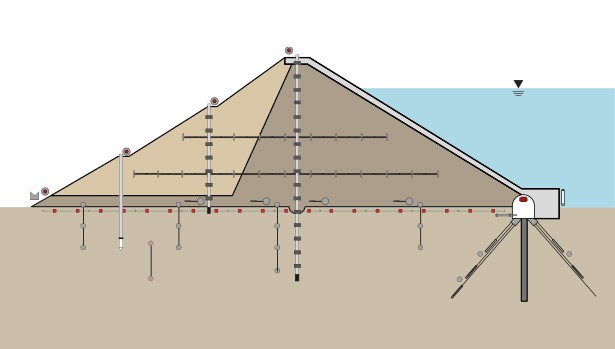

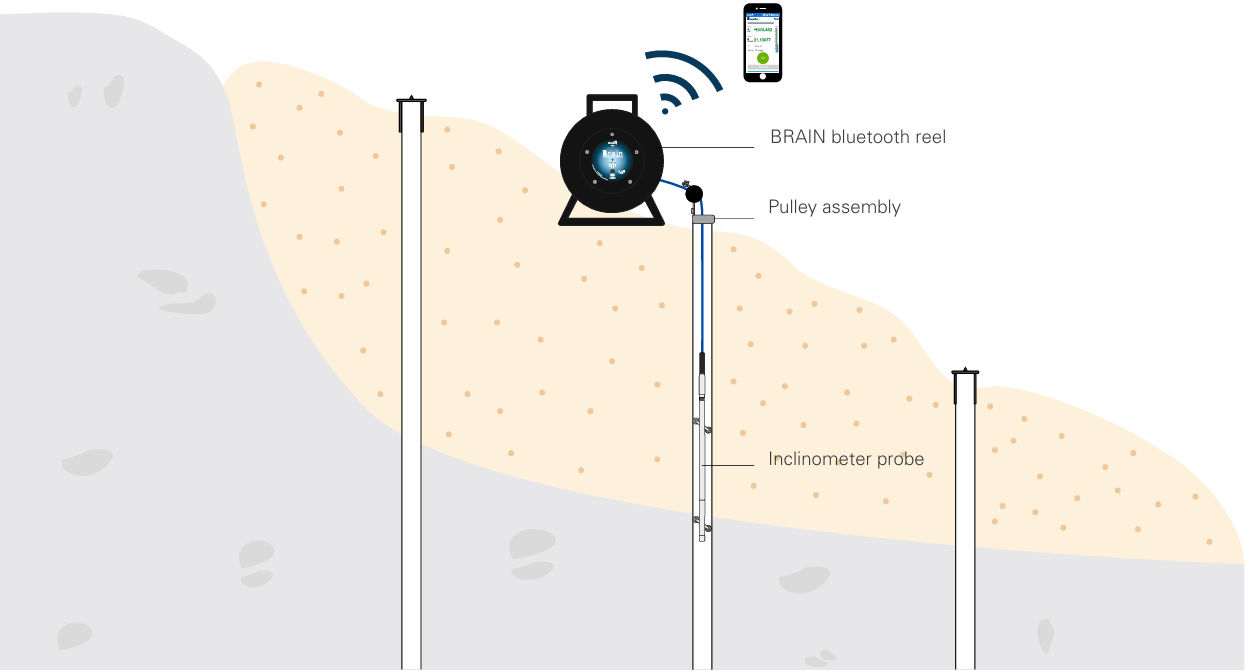

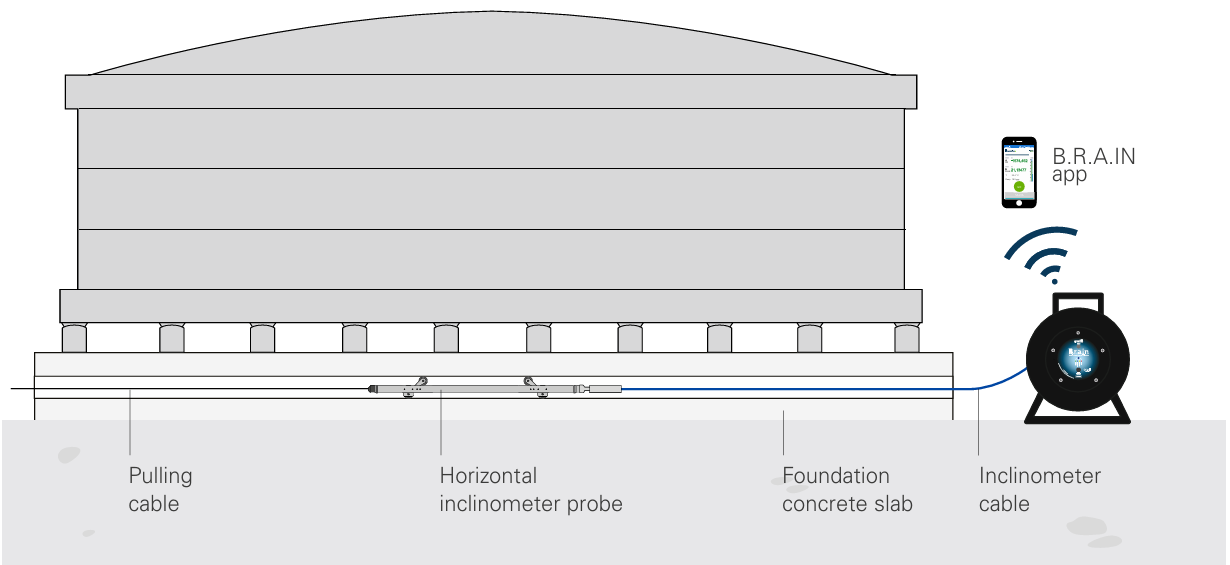

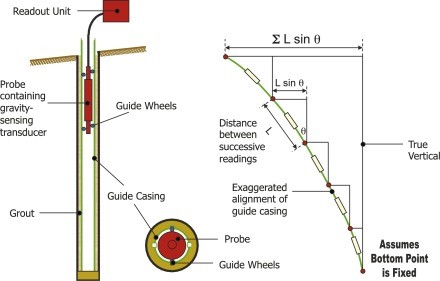

4. Inclinometer Monitoring (Inclinometers)

Introduction:

Inclinometers measure angular displacement or tilt of structures and ground surfaces. They are vital for detecting ground movement, such as landslides or foundation shifts, and ensuring the stability of infrastructures like tunnels or dams.

Test Procedure:

- Installation: Inclinometers are installed within a casing that is drilled into the ground along a vertical or near-vertical axis. This casing ensures that the inclinometer probe remains in position to detect any movement or tilt in the surrounding ground.

- Measurement: The inclinometer probe, which is equipped with tilt sensors, is lowered into the casing. The sensors measure the angle of displacement at various depths along the borehole. The probe is moved at set intervals to monitor movement at different levels.

- Data Acquisition: Displacement data is recorded as angular changes along the depth of the borehole. The data is stored and transmitted to a data logger for later analysis. Continuous measurements can be taken to monitor any significant movement.

- Calibration: Regular calibration is performed to ensure that the sensors are providing accurate angle measurements. This may involve verifying against known reference points and ensuring that no drifts occur in the measurement system.

Advantage:

- Accurate detection of small shifts in ground or structural movement.

- Continuous, long-term monitoring.

- Helps prevent potential structural failure or landslides.

Applicable Area:

- Geotechnical Engineering: Monitoring shifts in soil or structure positions.

- Mining Engineering: Monitoring subsurface stability.

- Civil Engineering: Ensuring safety in foundation construction or large infrastructure projects.

Future Scope:

- Integration with drone or remote sensing technology for larger-scale monitoring.

- Use of real-time monitoring for early warning systems in unstable areas.

- Enhancement of wireless inclinometer probes for easier installation.

Standard:

- ASTM D6235 – Standard Guide for Inclinometer Testing.

- ISO 9001 – Quality Management Systems.

5. Settlement Monitoring (Settlement Plates)

Introduction:

Settlement plates are used to monitor vertical displacement or subsidence of the ground or structures. These are commonly used in areas where soil compaction or structural settlement could lead to safety issues.

Test Procedure:

- Installation: Settlement plates are installed on the ground surface or embedded in the foundation of a structure. The plates are typically made of durable materials such as metal or concrete and are precisely leveled during installation.

- Measurement: The displacement of the settlement plate is monitored using precision leveling instruments, such as a laser or total station, which measure vertical displacement over time.

- Data Acquisition: The vertical displacement is recorded at scheduled intervals, and data is transferred to a central system for analysis. This allows monitoring of settlement trends and helps detect any abnormal or excessive movement.

Advantage:

- Simple and cost-effective for surface-level monitoring.

- Provides essential data for assessing foundation stability.

- Helps in evaluating the effects of nearby construction or excavation.

Applicable Area:

- Construction Sites: Monitoring settlement around buildings and foundations.

- Infrastructure Projects: Ensuring stability of roads, bridges, and other structures.

- Geotechnical Engineering: Detecting soil compaction and subsidence.

Future Scope:

- Integration with remote sensing for continuous monitoring.

- Use of automated settlement measurement systems.

- Potential use in assessing long-term subsidence in areas with high groundwater extraction.

Standard:

- ISO 19057:2018 – Geotechnical investigation and testing — Site monitoring using settlement markers.

6. Extensometer Monitoring (Extensometers)

Introduction:

Extensometers are devices used to measure the change in length (elongation or compression) of soil, rock, or structural elements. They are commonly used in geotechnical engineering to monitor subsurface movements or deformation in materials like soil, rock, and concrete. Extensometers are crucial for assessing the stability of foundations, tunnels, and slopes.

Test Procedure:

- Installation: Extensometers are installed to measure the elongation or compression of a specific soil or rock layer. The instrument is typically mounted on a surface plate or anchored into a borehole at the desired depth.

- Measurement: The extensometer consists of a measuring rod or cable connected to displacement sensors. These sensors detect changes in length caused by soil movement or deformation in the rock. The device is designed to capture even the slightest elongation or shortening.

- Data Acquisition: Data is collected either manually or automatically through a data logger that records displacement over time. This data is typically logged at regular intervals to monitor ongoing changes.

Advantage:

- High precision: Detects small changes in length, providing accurate data on material deformation.

- Long-term monitoring: Effective for long-term monitoring of subsurface or structural movements.

- Versatile: Suitable for both surface and deep borehole applications.

Applicable Area:

- Geotechnical Engineering: Monitoring the stability of slopes, embankments, and underground tunnels.

- Mining Engineering: Measuring ground deformation during excavation.

- Civil Engineering: Assessing the stability of foundations, bridges, and dams.

Future Scope:

- Integration with remote sensing: Enhanced data collection through wireless communication and IoT-based systems.

- Automated monitoring: Increased use of automation and AI for real-time monitoring and predictive modelling of ground behavior.

- Smart extensometers: Development of self-calibrating and energy-efficient models for harsh environments.

Standard:

- ASTM D6235 – Standard Guide for Inclinometer Testing.

- ISO 22282-1 – Geotechnical investigation and testing — Measurement of displacement.

7. Strain Monitoring (Strain Gauges)

Introduction:

Strain gauges are devices used to measure the strain (deformation) of materials subjected to stress. These are widely used in geotechnical and civil engineering to monitor structural health and ground movement. Strain gauges are particularly effective in monitoring stress on tunnels, bridges, dams, and other critical infrastructure.

Test Procedure:

- Installation: Strain gauges are typically bonded directly to the surface of the material being monitored (e.g., concrete, metal, or soil). The gauge measures the change in the material’s shape (strain) when subjected to stress. The installation often involves attaching the strain gauge to a clean, prepared surface using an adhesive.

- Measurement: Strain gauges work by detecting minute changes in resistance caused by the deformation of the surface. As the material strains (stretches or compresses), the resistance of the gauge changes, which can be directly correlated with the amount of strain.

- Data Acquisition: Strain data is collected either continuously or at intervals, depending on the application. This data is transmitted to a control unit, where it is logged and analysed.

Advantage:

- High sensitivity: Capable of measuring minute deformations that could lead to failure if left undetected.

- Real-time data: Provides continuous strain measurements for timely analysis and intervention.

- Cost-effective: Relatively inexpensive compared to other monitoring devices with similar precision.

Applicable Area:

- Structural Health Monitoring: Monitoring stress and strain in bridges, buildings, and dams.

- Geotechnical Engineering: Monitoring deformation in underground structures like tunnels and shafts.

- Civil Engineering: Assessing strain in pavements and other civil structures during load testing.

Future Scope:

- Wireless strain gauges: Development of wireless systems for easier installation and remote monitoring.

- Integration with IoT: Combining strain gauges with IoT devices for real-time data transmission and analysis.

- Smart materials: Use of smart strain gauges that can self-adjust or calibrate in changing environmental conditions.

Standard:

- ASTM E4 – Standard Practices for Force Verification of Testing Machines.

- ISO 12693 – Strain gauge applications for structural and geotechnical monitoring.

8. Deformation Monitoring (Total Stations/GPS Monitoring)

Introduction:

Deformation monitoring using Total Stations and GPS systems is essential for detecting and measuring movements in the Earth’s surface or man-made structures. Total Stations measure horizontal and vertical displacement through precise angular and distance measurements, while GPS systems track spatial coordinates in real-time to monitor 3D displacement.

Test Procedure:

- Installation: Deformation monitoring systems like Total Stations or GPS units are typically installed on fixed points, either on the ground surface or on structures. Total Stations use electronic theodolites to measure angles and distances, while GPS systems track the position of points on the Earth’s surface with high precision.

- Measurement: Total Stations measure the displacement of specific reference points over time, recording changes in distance, angle, or both. GPS systems, on the other hand, track the coordinates of the monitoring points, providing highly accurate 3D displacement data.

- Data Acquisition: Measurements are taken at predetermined intervals and are transmitted to a central system for storage and analysis. In some cases, continuous real-time data is available, providing immediate updates on any displacements.

Advantage:

- High precision: Provides accurate displacement data with sub-millimetre resolution in some cases.

- Real-time monitoring: Total Stations and GPS systems can provide continuous, real-time data for quick decision-making.

- Versatility: Suitable for large-scale infrastructure projects, including bridges, buildings, and transportation networks.

Applicable Area:

- Civil Engineering: Monitoring the deformation of large structures such as bridges, dams, and buildings.

- Geotechnical Engineering: Detecting ground movements such as settlement, slope movement, and subsidence.

- Mining and Tunnel Engineering: Monitoring the stability of mining excavations and underground structures.

Future Scope:

- Integration with drones: Use of drones with GPS systems for large-scale monitoring in hard-to-reach areas.

- Data fusion: Combining Total Station and GPS data with other geophysical survey data for more comprehensive analysis.

- Real-time predictive analysis: Leveraging machine learning and AI for predictive modelling of ground or structural movements.

Standard:

- ISO 17123-6 – Field procedures for testing geodetic and surveying instruments.

- ASTM D6913 – Standard Guide for Measuring and Reporting Movement in Structures Using GPS.

Contributing to Smart Bangladesh Mission through GROUND MONITORING SURVEY:

QC LAB Service. can play a significant role in creating a “Digital Bangladesh” and contributing to the “Digital Bangladesh Mission 2041” by leveraging your expertise in Ground Monitoring Surveys. Here’s how:

1. Infrastructure Development:

- Ground Condition Assessment for Planning: Utilize ground monitoring data (such as water levels, soil settlement, and strain measurements) to assess the suitability of land for infrastructure development, including roads, bridges, and buildings. This ensures that new projects are grounded in accurate, real-time data for optimal design and execution.

- Monitoring for Smart Infrastructure: Use extensometers, inclinometers, and settlement plates to track any changes in the ground that may affect the integrity of existing and upcoming infrastructure, particularly in areas vulnerable to land subsidence or shifts.

Main Users in Bangladesh: LGED, RHD, BBA, DMTCL, DNCC, RAJUK, WASA, City Corporation, PWD, Railway and private sectors involved in construction, energy, and urban development.

2. Disaster Management and Resilience:

- Monitoring Ground Movement and Stability: Use inclinometer and piezometer data to identify vulnerable areas prone to landslides, earthquakes, and other natural hazards. This data is critical for developing resilient infrastructure and planning for natural disaster response.

- Flood and Settlement Risk Mapping: Water level monitoring and ground settlement tracking can aid in creating disaster-preparedness plans, particularly in flood-prone areas, ensuring that communities are protected from long-term environmental changes.

Applications: Local government agencies such as DNCC, DSCC, and RAJUK, along with disaster management bodies like the Ministry of Disaster Management & Relief and DDM.

3. Smart City Initiatives:

- Subsurface Infrastructure Mapping: Use geophysical surveys and ground monitoring tools to map underground utilities and structures, preventing damage during the construction of smart city infrastructure such as fiber optics, sewage systems, and metro rail.

- Environmental and Ground Quality Monitoring: Continuously monitor environmental factors like soil and groundwater conditions, which are essential for maintaining sustainable, green urban environments in smart cities.

Key Stakeholders: RAJUK, WASA, PWD, and city corporations involved in urban planning.

4. Data Integration and Management:

- Geospatial Data Integration for Digital Platforms: High-resolution data from ground monitoring instruments can be integrated into Geographic Information Systems (GIS) and other digital platforms, enabling smarter decision-making in urban and environmental planning.

- Improved Data Accuracy: Continuous monitoring and real-time data collection from sensors, such as piezometers and strain gauges, ensure accurate and reliable geospatial data, critical for data-driven urban planning and management.

Collaborators: Government bodies like LGED, RHD, PWD, WASA, RRI, and private sector players in tech and construction.

5. Support for Remote Sensing Technologies:

- Integration with Remote Sensing: Combine data from ground monitoring tools with satellite and drone-based remote sensing systems to create a comprehensive understanding of land subsidence, infrastructure movements, and environmental changes.

- Enhanced Resource and Urban Management: By utilizing integrated data from multiple sources, we can improve resource management and urban monitoring, contributing to more efficient infrastructure development and urban planning.

Relevant Agencies: Government agencies, tech firms, and research institutions involved in data integration for national and urban development.

6. Collaborations and Partnerships:

- Public-Private Partnerships: Work alongside government agencies, technology companies, and universities to implement advanced ground monitoring solutions that support national digital initiatives and smart city development.

- Capacity Building and Knowledge Transfer: Conduct training sessions and workshops to build local capacity in ground monitoring techniques, ensuring sustainable technological development within Bangladesh.

Potential Collaborators: Ministry of Science and Technology, academic institutions, tech companies, and government agencies like LGED, PWD, RHD, BBA, RRI, City Corporation and RAJUK etc.

7. Innovation and Research:

- Cutting-edge Monitoring Technologies: Explore and implement innovative ground monitoring techniques such as wireless sensors, AI-powered data analysis, and remote monitoring to push the boundaries of current infrastructure management practices.

- Research for Future Growth: Engage in R&D to improve ground monitoring systems, providing solutions that can handle complex urban challenges, such as smart city development, climate resilience, and sustainable construction.

Focus Areas: Innovations in remote sensing, AI integration, and real-time monitoring technologies.

Through these strategies, QC LAB Service. contribute to a more robust, technologically advanced, and sustainable “Smart Bangladesh” by leveraging its expertise in ground monitoring and helping integrate these technologies into critical national development goals.

Ground monitoring survey plays a pivotal role in supporting the development of a Smart Bangladesh by providing critical data and insights for infrastructure development, disaster resilience, and urban planning. By utilizing advanced instruments like extensometers, piezometers, inclinometers, and GPS systems, QC LAB Service. can significantly contribute to the country’s vision of sustainable growth and technological advancement.

Through collaboration with government bodies, data integration into digital platforms, and the adoption of cutting-edge technologies, we can enhance the country’s ability to address pressing challenges such as climate resilience, urbanization, and resource management. The implementation of robust ground monitoring survey systems ensures that the nation’s infrastructure is resilient, safe, and capable of supporting smart city initiatives for the future.

As Bangladesh moves toward its Digital Bangladesh Mission 2041 and Smart Bangladesh goals, QC LAB Service. stands ready to play a key role in making these ambitions a reality, driving innovation, and contributing to the nation’s overall digital and infrastructural transformation. Through continuous research, data-driven insights, and state-of-the-art technology, the foundation for a sustainable, smart, and resilient Bangladesh can be laid, ensuring a better quality of life for all citizens.