Rebar Locator and Concrete Cover Meter:

In the realm of construction and infrastructure maintenance, ensuring the strength and durability of concrete structures is critical for both safety and longevity. While concrete may appear solid from the outside, its internal reinforcement can sometimes be difficult to assess with traditional methods. Hidden issues such as improperly placed rebar, insufficient cover of a structure. This is where Rebar Locators and Concrete Cover Meters play an essential role— advanced, non-destructive testing (NDT) tools designed to accurately locate reinforcement and measure cover depth within concrete.

Rebar locator and concrete cover meter has both the facilities where Rebar Locators features use electromagnetic signals to detect and map the position of steel reinforcement bars (rebar) within concrete structures. By providing precise information on the location and spacing of rebar’s, these devices help ensure that the structure’s reinforcement meets design specifications. Meanwhile, Concrete Cover Meters features measure the depth of the concrete cover, ensuring that it is adequate to protect the rebar from environmental factors such as moisture and corrosion.

Together, this tools provide engineers with fast, reliable, and non-invasive ways to assess critical reinforcement and concrete cover conditions. This allows for early detection of potential issues, enabling proactive maintenance and repair measures that help prevent long-term damage and ensure the structural integrity of concrete constructions.

Market Size and Growth:

Market Size:

The global market for non-destructive testing (NDT) technologies, including Rebar Locators and Concrete Cover Meters, is witnessing significant growth. As the construction industry continues to prioritize structural integrity and safety, the demand for accurate and efficient tools to inspect concrete reinforcement is on the rise. Rebar locators and concrete cover meters have become indispensable in assessing the location, depth, and condition of reinforcement bars in concrete structures. Industries such as construction, civil engineering, infrastructure maintenance, and real estate development are driving the demand for these tools.

Key sectors, including government agencies, infrastructure maintenance companies, and engineering firms, are increasingly adopting rebar locators and cover meters for inspections and evaluations of bridges, highways, buildings, and other concrete structures. The ability to inspect concrete structures without causing any disruption or damage makes these devices highly valued in both preventive and routine maintenance procedures.

In regions like North America, Europe, and Asia-Pacific, where there is an increasing emphasis on infrastructure longevity and the upkeep of aging structures, the demand for rebar locators and concrete cover meters is expected to remain robust. Additionally, emerging markets in countries undergoing rapid urbanization are showing growing interest in adopting non-destructive testing technologies to ensure the quality and safety of their growing infrastructure projects.

Growth Rate:

The market for rebar locators and concrete cover meters is projected to grow steadily in the coming years. This growth is driven by the increasing focus on infrastructure maintenance, the need for accurate reinforcement mapping, and government regulations aimed at ensuring the safety of public structures. The growing awareness of the importance of preventing reinforcement corrosion and early detection of potential structural weaknesses is also contributing to market expansion.

Technological innovations, such as the integration of advanced sensors, real-time data analytics, and wireless communication capabilities, are expected to propel the market forward. Moreover, the rising demand for cost-effective and time-efficient inspection methods, particularly in the maintenance of large-scale infrastructure—further enhances the appeal of this tools. With the global push toward ensuring the safety and durability of concrete structures, rebar locators and concrete cover meters are poised to become vital tools in both new construction and the rehabilitation of aging infrastructure.

Key Technologies of Rebar Locator and Concrete Cover Meter

- Electromagnetic Induction Technology

At the core of Rebar Locators is electromagnetic induction, which is used to detect the presence and location of steel reinforcement bars (rebar’s) within concrete structures. The device generates an electromagnetic field that interacts with the metal in the rebar. The rebar disturbs the electromagnetic field, allowing the locator to detect its position. This technology enables accurate mapping of reinforcement without the need for drilling or destructive testing.

- Concrete Cover Measurement via Magnetic Field

Concrete Cover Meters measure the depth of concrete cover by detecting the strength of the magnetic field around the rebar. A sensor emits a magnetic field that is altered by the presence of the rebar and the concrete cover surrounding it. The device analyses the intensity of the magnetic field to calculate the thickness of the concrete cover, ensuring it meets the specified requirements for rebar protection.

- Pulse Induction Technology

Pulse Induction is another technique used in advanced Rebar Locators, where short pulses of magnetic field are sent into the concrete. When these pulses encounter metal objects such as rebar, they induce a response that is measured by the system. The location and depth of the reinforcement can be accurately identified by analysing the strength and timing of the pulse response, making this method ideal for both locating rebar’s and assessing the depth of concrete cover.

- Multi-Depth Measurement Capabilities

Many modern Rebar Locators and Concrete Cover Meters feature multi-depth measurement capabilities. These tools can detect rebar at various depths within the concrete, allowing engineers to map out the full extent of reinforcement. This is essential for ensuring that structural designs are adhered to and helps assess whether the rebar’s placement is sufficient for structural integrity.

- Data Processing and Mapping

Rebar locators and cover meters are often integrated with advanced data processing software that can create visual representations of the reinforcement layout and concrete cover depth. The data captured during the inspection is analysed, and 2D or 3D maps are generated to help engineers visualize the internal structure. This aids in planning repairs, monitoring reinforcement condition, and ensuring that safety standards are met.

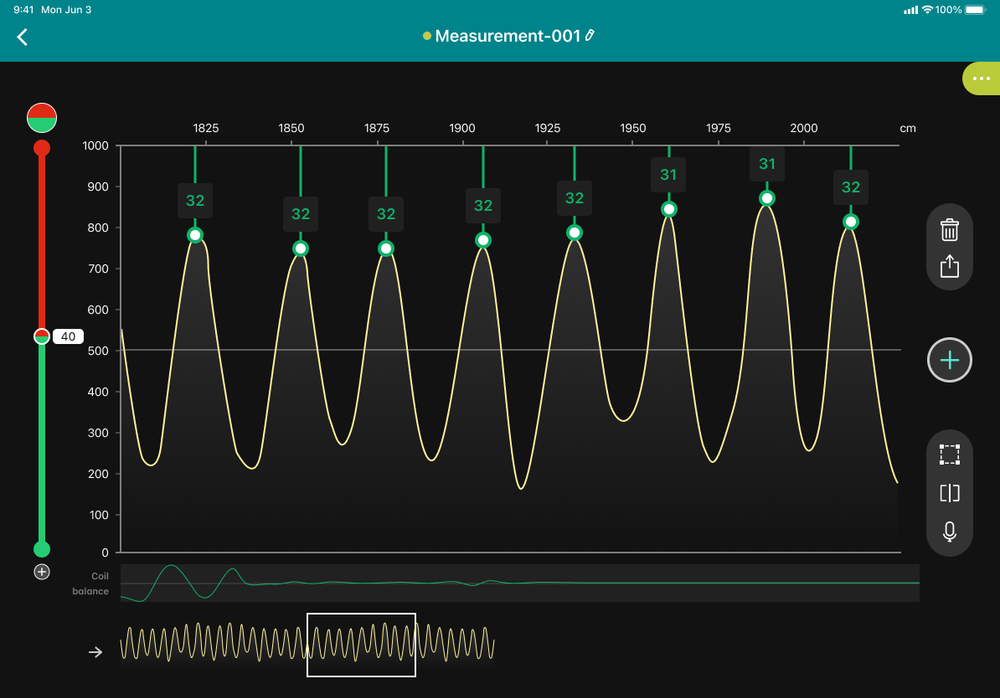

- Real-Time Visualization

Rebar Locators and Concrete Cover Meters typically offer real-time visualization of the data collected during the inspection. Engineers can instantly see the location of rebar’s and measure the cover depth on a display screen, allowing for immediate analysis and decision-making. This real-time feedback enhances the efficiency of the inspection process and helps engineers identify potential problem areas without delay.

- Wireless Connectivity and Data Sharing

Modern Rebar Locators and Concrete Cover Meters systems feature wireless connectivity that allows for seamless data transfer to mobile devices, cloud storage, or integrated management systems. This technology enhances collaboration among engineering teams, as data can be shared instantly across multiple devices. It also allows for easier reporting and long-term monitoring of structural conditions.

- Automation and Advanced Algorithms

Some advanced Rebar Locators and Concrete Cover Meters use automated algorithms to detect and highlight areas where the rebar placement or cover depth may be inconsistent or outside specified parameters. These systems can automatically flag potential issues, increasing the accuracy and speed of inspections.

QC LAB SERVICE, Role:

As a trusted provider of advanced non-destructive testing (NDT) solutions, QC LAB Service. is committed to offering cutting-edge technology that ensures accurate and reliable evaluations of concrete reinforcement and cover. By utilizing state-of-the-art Rebar Locators and Concrete Cover Meters, we enable our clients to make informed decisions about the integrity of their concrete structures. Our tools help identify reinforcement placement, measure cover depth, and assess potential vulnerabilities, ensuring that every project adheres to safety standards and is built to last.

Bringing Global Expertise to Local Infrastructure

At QC LAB Service., we combine global technological innovations with local expertise to deliver top-tier solutions for concrete inspection. Here’s how we are making a significant impact:

Adopting and Customizing Rebar Locators and Cover Meters: By leveraging the latest Rebar Locator and Concrete Cover Meter technologies, we provide our clients with precise data on the location of reinforcement and the depth of concrete cover. These tools allow us to offer detailed, accurate assessments that help optimize structural safety and compliance with design specifications.

Training and Knowledge Transfer: To ensure the effective use of these technologies, we offer specialized training sessions for engineers and technicians. Our workshops cover the operation of Rebar Locators and Concrete Cover Meters, as well as the interpretation of results. This empowers our local workforce with the skills needed to perform comprehensive and accurate concrete evaluations confidently.

Collaborative Efforts for Continuous Improvement: We collaborate with international experts and institutions to stay at the forefront of testing technology. By integrating global innovations with local industry standards, we enhance the reliability and accuracy of our services, providing unmatched value for every project.

Support for Growing Infrastructure Needs

As the demand for reliable and efficient structural evaluations continues to grow, our Rebar Locators and Concrete Cover Meters play a critical role in addressing these challenges. With an unwavering commitment to quality and technological advancement, QC LAB Service. ensures that our clients benefit from the most accurate, efficient, and cost-effective solutions available, helping to maintain the safety and longevity of their infrastructure.

Contributing to Digital Bangladesh with Rebar Locator and Concrete Cover Meter:

QC LAB Service. is proud to support the vision of a Digital Bangladesh by incorporating advanced Rebar Locators and Concrete Cover Meters into infrastructure evaluation and management. Here’s how we are contributing:

Digital Integration for Structural Assessments: Rebar Locators and Concrete Cover Meters provide precise and actionable data on the positioning of rebar and the depth of concrete cover. This data can be integrated into digital platforms like Geographic Information Systems (GIS) and Building Information Modelling (BIM), allowing for seamless monitoring and management of infrastructure. With real-time, accurate data at their fingertips, engineers and urban planners can make informed decisions about the maintenance and development of concrete structures.

Real-Time Solutions for Proactive Infrastructure Maintenance: The data from Rebar Locators and Concrete Cover Meters can be fed into software and mobile applications, offering real-time updates on the condition of concrete reinforcements and cover depth. This technology supports the timely identification of potential structural issues, ensuring efficient management of urban infrastructure and facilitating more responsive and proactive maintenance efforts.

Smart Planning for Sustainable Urban Growth: By accurately mapping rebar placement and measuring cover depth, these tools help identify areas where reinforcement may be insufficient or vulnerable to corrosion. Early detection aids in smarter urban planning, fostering the development of safer, more sustainable cities in line with the goals of Digital Bangladesh. This ensures that new and existing infrastructure can be maintained and enhanced for long-term resilience.

Cost-Effective and Sustainable Infrastructure Management: Rebar Locators and Concrete Cover Meters enable early detection of structural problems, which can help prioritize maintenance efforts and reduce the need for expensive repairs. By contributing to proactive maintenance, these tools play a crucial role in creating a cost-effective and sustainable infrastructure management system, which is essential for the continued growth and development of Bangladesh.

Test Procedure for Rebar Locator and Concrete Cover Meter

- Preparation:

Begin by setting up the Rebar Locator and Concrete Cover Meter, ensuring that the equipment is calibrated properly based on the type of concrete and the specific requirements of the structure. Ensure the sensor is clean and functioning, and that the device is ready for accurate readings. Select the appropriate mode based on whether you are detecting rebar or measuring the concrete cover.

- Test Execution:

Position the Rebar Locator or Concrete Cover Meter on the test surface, ensuring direct contact with the concrete. For the Rebar Locator, the device will emit an electromagnetic field or pulse that interacts with the rebar inside the concrete. For the Concrete Cover Meter, the sensor will measure the magnetic field to determine the depth of the cover surrounding the rebar. Both devices will then provide real-time readings based on the interaction with the internal structures.

- Data Acquisition:

The system captures the responses from the rebar and concrete cover. For the Rebar Locator, this data will include the location and depth of rebar’s, and for the Concrete Cover Meter, the readings will include the thickness of the concrete cover. These signals are processed in real time, providing a map of reinforcement locations and concrete cover depth, which helps identify any inconsistencies or areas of concern.

- Data Analysis:

The acquired data is reviewed and analyzed by specialists, who interpret the readings to determine the location, spacing, and depth of rebar, as well as the thickness of the concrete cover. Any deviations from the expected values, such as insufficient cover depth or improper rebar placement, are flagged. This analysis helps assess the integrity of the structure and ensures compliance with design standards.

- Reporting:

A comprehensive report is generated, which includes graphical representations, such as images or 2D/3D maps of the reinforcement layout and concrete cover. The report will highlight areas where rebar placement or cover depth may not meet specifications, along with recommendations for corrective actions, further testing, or maintenance measures.

Advantages of Using Rebar Locator and Concrete Cover Meter

Non-Invasive: Rebar Locators and Concrete Cover Meters are non-destructive testing tools, meaning they assess the internal condition of concrete structures without causing any damage. This ensures minimal disruption to existing structures, eliminating the need for costly repairs or rebuilding.

Real-Time Results: These devices provide immediate feedback, offering real-time data on the location of rebar and the depth of concrete cover. This instant information allows engineers and contractors to make quick decisions during inspections, ensuring that maintenance or construction activities are not delayed.

High Accuracy: Rebar Locators and Concrete Cover Meters offer high-precision measurements, accurately locating reinforcement bars and assessing the concrete cover depth. This ensures that any irregularities, such as insufficient cover or improper rebar placement, are detected early, helping to prevent long-term structural issues.

High Accuracy: Rebar Locators and Concrete Cover Meters offer high-precision measurements, accurately locating reinforcement bars and assessing the concrete cover depth. This ensures that any irregularities, such as insufficient cover or improper rebar placement, are detected early, helping to prevent long-term structural issues.

Cost-Effective: By identifying potential problems before they escalate, Rebar Locators and Concrete Cover Meters help avoid costly repairs, unnecessary demolition, or delays caused by undetected structural issues. These tools provide a cost-effective solution for assessing the condition of concrete structures with minimal disruption.

Comprehensive Coverage: Rebar Locators and Concrete Cover Meters can be used on various concrete structures, offering a broad scope of applications. They provide essential insights into reinforcement placement and concrete cover, which are critical for the structural safety of bridges, buildings, roads, and other infrastructure projects.

Future Scope of Rebar Locator and Concrete Cover Meter

Advancements in Data Processing and AI: Integration of AI and machine learning will improve the speed, precision, and predictive capabilities of Rebar Locators and Concrete Cover Meters, enabling better analysis of structural integrity and proactive maintenance.

Smart Infrastructure Integration: As cities evolve, these tools will integrate with smart infrastructure systems for real-time monitoring, improving resource management and ensuring safer, more sustainable urban development.

Collaboration with Other Technologies: Combining Rebar Locators and Concrete Cover Meters with technologies like Ground Penetrating Radar (GPR) will offer a more comprehensive structural analysis, enhancing accuracy in construction and infrastructure planning.

Enhanced Portability and User-Friendly Design: Future models will become more portable, compact, and easier to use, making structural assessments more efficient and accessible in diverse environments.

Cloud-Based Data Storage: Cloud integration will enable real-time and historical data access, supporting long-term monitoring and improving asset management strategies for infrastructure projects.

QC LAB Service. is committed to enhancing infrastructure assessment through the use of Rebar Locators and Concrete Cover Meters. These advanced, non-destructive tools offer accurate, real-time insights into the structural integrity of concrete, enabling more efficient inspections, cost-effective maintenance, and reduced disruption to existing structures. By integrating these technologies, QC LAB Service. is contributing to the creation of safer, more resilient urban environments. As innovations in data processing, smart infrastructure, and cross-technology integration continue to evolve, QC LAB Service. will remain a leader in structural health monitoring, ensuring the sustainable development and longevity of critical infrastructure.