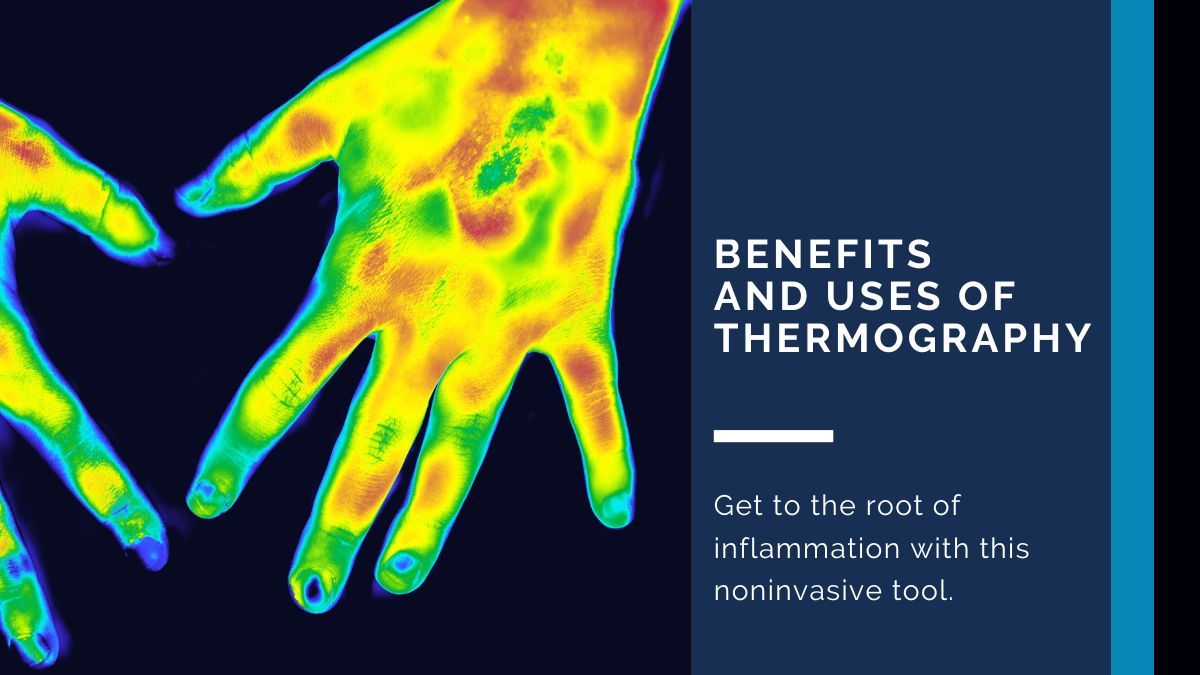

Infrared thermography Services is a technique of using a non-contact & non-destructive Infrared Scanning Camera to detect invisible Infrared thermal radiation of objects, and recording these pictures as thermal images called “Thermograms” to assist in identifying potential equipment failures.

Infrared thermography Services is a proactive troubleshooting and predictive maintenance tool. The test method uses an infrared imaging to detect, display and record thermal patterns and temperature across the surface of an object

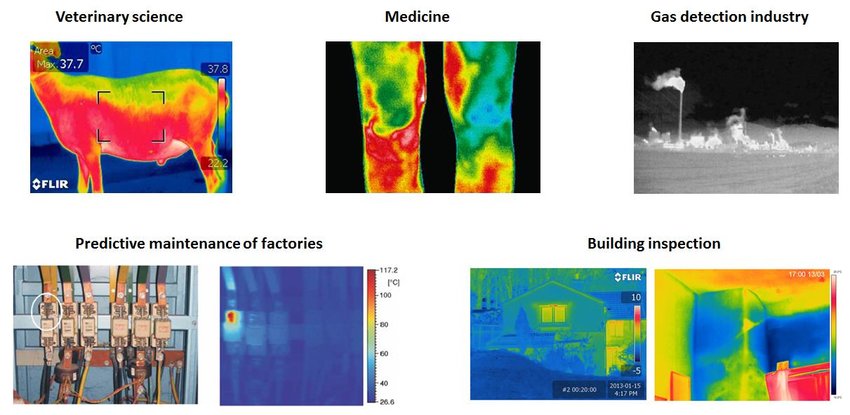

Infrared thermography is a valuable tool for condition monitoring and preventive maintenance. Not only does it allow you to detect thermal abnormalities of machines, but it lets you do so in a non-intrusive, hands-off way while still getting results in real-time.

QC LAB provides Infrared Thermography Services, comprising Survey of Electrical installations (MCC & PCC panel, switchgears, motor junction box terminal, switchyards etc.) and mechanical equipment (compressor, pipe leakage, refractories etc.)

Our team consisting of professional experts carry out high quality Thermography Testing activities of any magnitude, to the entire satisfaction of the Clients.