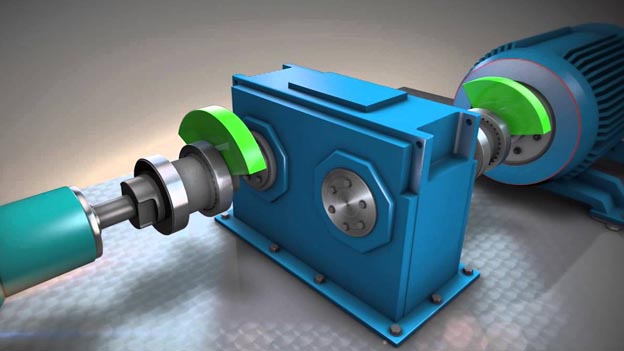

Shaft alignment is a process to make two or more rotating shafts co-linear, or in the same straight line, both vertically and horizontally.

Laser Shaft alignment ensure precise and accurate alignment within very short time. Machines runs longer through its life and also helps user save power consumption for the rotary machines.

Generally, Shaft alignment is often called coupled alignment.

QC LAB 24 is a leading provider of Industrial Laser Shaft Alignment services in Bangladesh & abroad. In experienced hands lasers are much quicker and will result in a more accurate alignment.

We have provided alignment services for over 20 years. With a range of global customer locations and a full team of engineers, technicians, and support staff, we are able to accurately provide your alignment services in the time frame you need. From optical, laser and mechanical.

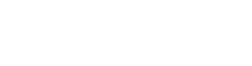

Rotating machines are prone to misalignment. Correctly aligned and regularly controlled machines significantly reduce operating and maintenance costs. Conventional methods for shaft alignment, such as straightedge, thickness gauge or dial gauge, are very time consuming. The quality of the results is also highly dependent on the experience of the operator.

If misalignment is left uncorrected, unnecessary stress can be put on bearings, seals, and other components resulting in premature failure. A precision laser alignment will also increase the efficiency of the machine, which will use less energy and result in substantial cost savings in utility bills.